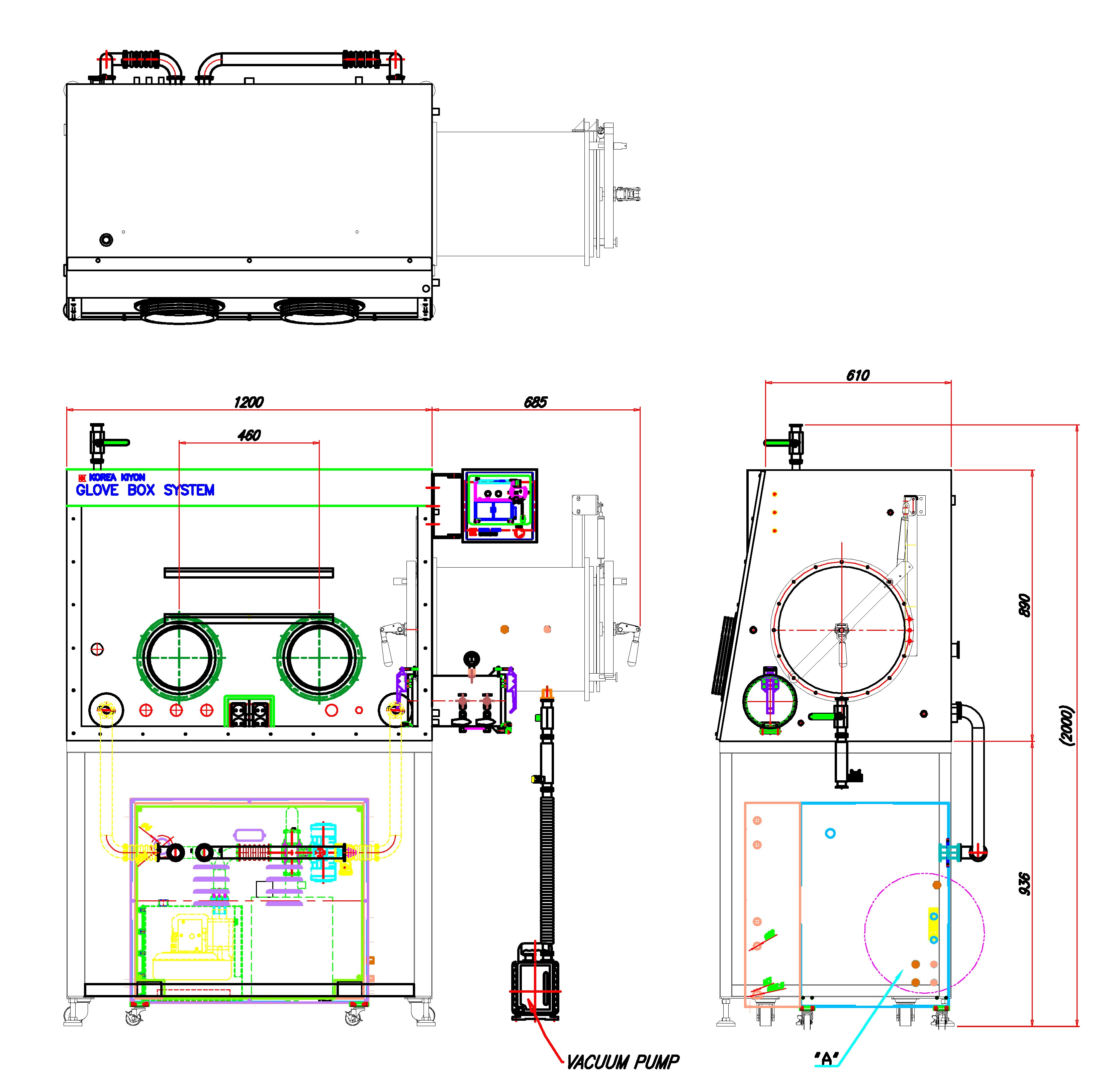

Model: KK-011AS

Glove box is designed to provide a hermetically sealed and highly customized working space under a very tightly controlled atmospheric environment; less than 1 ppm of Oxygen and Moisture concentration levels. Glove box expansion features include additional antechambers for flow processes, cold storage freezers, process vacuum ovens and furnaces and full line of accessories.

Features

1) Glove Box

- Single length and Single Sided (2 port): 1,200(L) X 890(H) X 760(D)mm

- Modular structure with elastomer gasket front panel

- Material: 304 Stainless Steel, Main body: 4mm thick

- Side end panel: 4mm thick, 3 micron filter: 2 ea

- Fluorescent Skylight

- 8"Glove Port (M/C): 3 ea , Butyl Rubber Glove (9" dia.,15Mil thickness) : 1 pair

- Window : 10mm thick, Scratch & High impact resistant, Optically clear Polycarbonate

- 6 Stainless steel shelves inside chamber

- Electrical Outlet (1 ea.) : 220VAC x 4 receptacle x 15A

- Glove Port cover: Protect atmosphere during glove replacement

- Service port feedthrough: extra 2 NW40 ports

- Manual purge vent valve with KF Flange NW25

- Leakage Certification : No detectable leak at 17mbar with Helium spectrometer

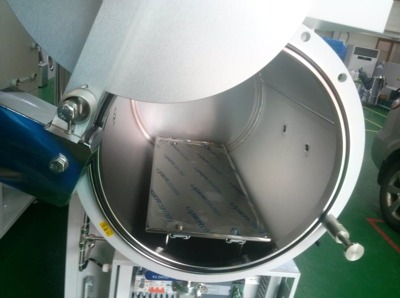

2) Large Antechamber

- Size: 380 inside dia. x 500mm length

- Vacuum capacity: 1 x 10-3 torr, Door is vertical action

- Tray : S/S Sliding Tray (200mm x 450mm)

- Vacuum gauge: Bourdon tube dial type

- Automatic Vacuum and Refill System

3) Mini Antechamber

- 150(dia.) x 290 (length)mm, Door : Single center clamped, O-ring

- Gauge : Bourdon tube dial type, vacuum : 1 x 10-3 torr

- Manual Vacuum and Refill System

4) Automatic Pressure Controller (7’’ full Color Touch Screen Panel)

- 12.5 to +12.5 mbar, Limits easily adjustable via PLC

- Read pressure and set limits, Manual foot switch operate whether automatic control is on or off

- Four solenoid valves are operated. Gas pressure: 10 to 30 psi. Approx. 25 psi

5) Dri Trap (Purification System)

- Circulation Blower: 106m³/h (Variable speed control, Max pressure: 5.9 Kpa, 220V, 3Ph, 60Hz)

- Working gas: N2 or Ar Gas for Circulation

- N2/H2 or Ar/H2 mixture gas for regeneration (H2 Gas: 3-5%)

- Automatic atmosphere reduction for 1 ppm atmosphere

- Oxygen/Moisture removal to less than 1 ppm

- Control: Programmable Logic Controller type

- Automatic purification regeneration process

- Electro-Pneumatic valve for regeneration

- Single Column Purifier: Purifier charger Capacity (Molecular sieve and Copper oxide)

6) Vacuum Pump (Double Stage)

- Direct drive oil-sealed rotary vane vacuum pump.

- Actual pumping speed: 21m³/h

- Ultimate pressure: 5 x 10¯3 torr.

- Inlet & Outlet Connection: NW25

- Oil capacity: 1.1 liter, weight: 24kg

- Oil mist trap with exhaust pipe & flange.

7) Support Stand

- 1200(L) x 930(H) x 760(D)mm, Type : 2 Door Cabinet Type.

- Material: SS400(Steel), Caster : Separate type 3" Foot Master , Height adjustable pad.

- Painting HF-BK006

8) Moisture Analyzer

- Model: DMT152

- Type: Thin-film capacitive polymer sensor

- Measurement range: 0 ~ 1,000ppm

- Accuracy: ±2℃

- Complies with EMC standard EN61325-1

9) Oxygen Trace Analyzer

- Model: LD-450-C(Converter), SD25NW(Sensor Unit)

- Measurement system: Zirconia Oxygen concentration cell

- Measurement range: 0.001ppm – 100%

- Display range: 0-1,000ppm

- Repeatability: ±0.5%FS or less 0-1% range or more ±1.0% FS or ±0.1ppm whichever is bigger or less than 0-1% range

- ^ back to top ^

2 Port Glove Box layout